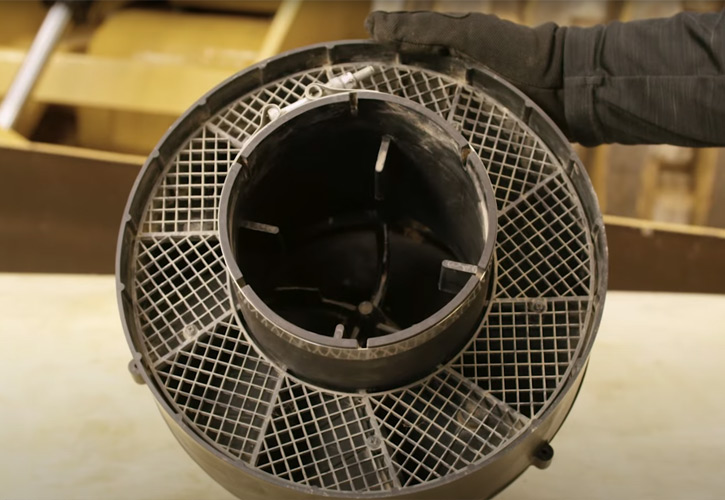

HOW TO SERVICE THE CAT® PRE-CLEANER ON AN ENGINE AIR FILTER

The pre-cleaner on your Cat machine helps extend engine air filter life as much as three times by trapping and ejecting debris before it ever reaches the air filter. Check out this video that shows you how to clear the pre-cleaner’s ports so debris can flow, and provides tips for… Read More

Read More >>

HOW TO INSPECT THE MAGNETIC PLUGS ON YOUR CAT® DRIVETRAIN

The multiple magnetic plugs on Cat drivetrains should be checked every 500 hours, or at intervals listed in your Operation and Maintenance Manual. This video demonstrates how to remove the plugs and classify the debris deposit that’s present under one of five Caterpilllar® wear ratings, and explains when it’s time… Read More

Read More >>

How to Use Cat® Extreme Application Grease

Cat Extreme Application Grease is designed to stay where it’s placed, resisting water washout and protecting against rust as it lubricates joints. There are two types of grease, and this video will show you how to decide which one you should be using, even as you grease five times less… Read More

Read More >>

THE BEST REASONS TO USE THE CAT® RENTAL STORE CUSTOMER PORTAL TO RENT AND MANAGE EQUIPMENT

Powering your equipment and your productivity starts with a reliable battery. That’s why Cat® batteries are designed to deliver unmatched performance, durability, and starting ability in temperature extremes when compared to other batteries... Read More

Read More >>

Three Factors That Increase Rubber Track and Undercarriage Wear – and How to Soften Their Impact

Cat® rubber tracks are designed and built to be robust and long-lasting as integral parts of the undercarriage system on compact track loaders (CTL) and mini excavators. They deliver unmatched suspension, traction, flotation, speed, productivity, and versatility in a wide range of environments. CTL and mini... Read More

Read More >>

Benefits Of Rebuilding Your Machine With Carter Machinery

When you partner with Carter Machinery, you get quality components and equipment manufactured to execute tasks with perfection. Our Cat® Certified Rebuild Program enables you to give a new life to older machines, components, and systems. We’ll help you restore them to good as new condition for a… Read More

Read More >>

HOW TO CHOOSE THE RIGHT UNDERCARRIAGE FOR YOUR EQUIPMENT

With so many different choices available, it can be overwhelming trying to evaluate and decide exactly which type of rubber track is the right one for your Cat® compact track loader, multi-terrain loader, or mini excavator. While a big part of that decision rests on two factors – budget and… Read More

Read More >>

Bucket Ground Engaging Tools: Selection, Changeouts, and Maintenance

Bucket ground engaging tools (GET) have a significant impact on equipment longevity, productivity, fuel consumption, and maintenance costs, which makes choosing the right GET and properly maintaining them two of the most important machine-related decisions owners and operators face. While bucket GET include base edges, adapters,… Read More

Read More >>

Get To Work on a New Construction Career

With October’s designation as Careers in Construction Month, now is the perfect time to consider how a construction career can take you to new heights. Carter Machinery knows the importance of spreading the word about the demand for construction jobs. According to Build Your Future – an advocacy… Read More

Read More >>

Benefits of ‘Wet’ Pin and Bushing Turns

Carter Machinery has a preventative maintenance program to fight that degradation process of pin and bushings, extending your machine’s life and saving you money both now and in the future. The Problem The steel components of a track-type machine’s undercarriage are constantly wearing down, slowly threatening your projects and… Read More

Read More >>